Extractor hoods:

high energy savings possible

Kitchen ventilation offers considerable potential for saving energy. This is the result of a comprehensive new study. Both the appliances themselves and their control systems, but also the exhaust and recirculating air ducting, can be optimised.

As an industrial partner of no fewer than three research institutes, with this study Naber has once again demonstrated its competence and innovative strength in the field of kitchen ventilation. All the factors that influence the efficiency of an extractor system and its components were examined: firstly, the extent to which the extractor hood is able to capture the humid cooking vapours, which are contaminated with odours and pollutants, and remove them from the living area. Then the options for using sensors to adjust the air throughput of the appliance, and thus the energy consumption, to the actual requirements. The energy loss through the exhaust air flap was also investigated, as were various types of air flow in exhaust air systems. And finally, the researchers focused on the impact of size and ageing behaviour on recirculating air filters.

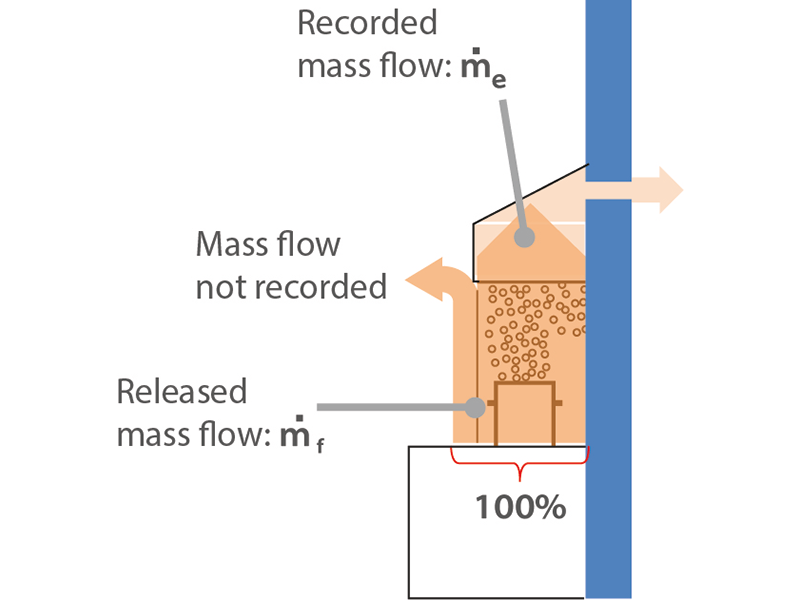

Considerable differences in performance

The degree of capture of five overhead hoods and three angled hoods, all in exhaust air mode, was investigated. There were significant differences in the capture of the vapours, the air throughput required for this and the power consumption. One particularly efficient hood removed 90 per cent of the cooking fumes from the room at only about 200 cubic metres per hour (m3/h). Other models need around 500 m3/h for the same degree of capture or achieve significantly lower cleaning efficiency. This also affects the power consumption of the appliance and the heating energy demand of the home, as less air throughput also means that less room air needs to be heated. Very good extractors cause only 80 kilowatt hours of heating energy demand per year (kWh/a) in the selected reference house (passive house, 156 m2 heated area, 0.5 hours of operation per day). Inferior appliances cause more than twice as much heating energy demand. This value is particularly high for hob extractors, for which the values were taken from a previous study: due to the high air volume required to extract the steam as it rises, the heating energy demand in exhaust air mode is more than three times higher than that of the best overhead hood.

In practice, the efficiency also largely depends on the air duct used. Here, with COMPAIR PRIME flow®, Naber offers an aerodynamically optimal system that can be installed very simply and flexibly either with flat or round ducts.

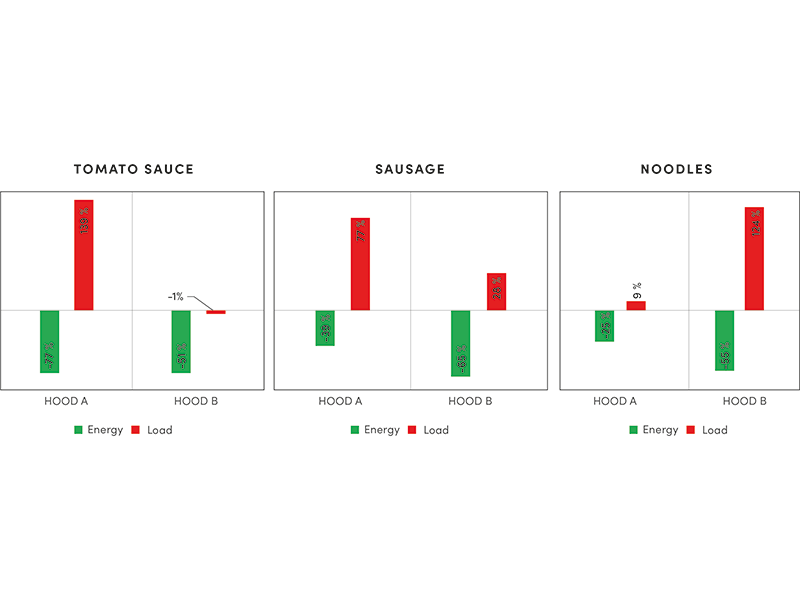

Sensors reduce power consumption

The extractor does not always have to run at full power. In the parboiling phase or at low hob temperatures, less air throughput is sufficient for good cleaning. “Here, sensors can detect the air quality, for example with regard to humidity or odours and pollutants (VOC), and regulate the extractor fan directly accordingly. Or indirect controls are used, for example via the number and temperature of the active cooking zones”, says Dr.-Ing. Alfred Bruns, who oversaw the study for Naber GmbH. Both variants reduced the power consumption compared to constant operation. “However, either the steam from cooking pasta or the odour from VOCs when frying was not properly removed. Therefore, a combination of both variants is probably the best way to combine low energy consumption and good cleaning results”, says Alfred Bruns, who heads the development department at Naber.

First-class results for Naber wall conducts

In newly built or renovated efficiency and passive houses, any leaks in the building envelope lead to a loss of home comforts for the occupants. Many wall conducts, exhaust air flaps and supply air vents are therefore unsuitable. The study showed that effective and particularly hygienic exhaust air technology for extractor systems is nevertheless possible in many cases, as shown by the wall conducts flow Star GTS (mechanical), BIXO (motorised) and the magnetic-mechanical THERMOBOX from Naber. Thanks to their sophisticated technology, the additional heat required to heat the ambient air is minimal, even in smaller flats. This results in significant energy savings compared to devices from the DIY store or a simple backflow flap on the extractor hood.

The study “Investigation of extractor systems in residential kitchens with regard to energetic, fluidic and hygienic aspects” was commissioned by the Federal Institute for Research on Building, Urban Affairs and Spatial Development (BBSR) and funded by the Federal Ministry for Housing, Urban Development and Building from the funds of the innovation programme Zukunft Bau. The Passive House Institute in Darmstadt, the ITG Institute for Building Systems Engineering Research and Application and the Institute for Wood Technology, both in Dresden, as well as the company Naber from Nordhorn were involved.

Press photos

We expressly point out that due to the image rights transferred to us, the use of the attached images is only permitted for advertising products purchased from Naber. Naber is always entitled to prohibit the use of data or images/illustrations/graphics in a reasonable time frame. Processing or redesigning the material is only permitted to the extent that the identity of the material, in particular of the brands and features, is not changed. It is not permitted to pass on the data or images/illustrations/graphics to third parties or to transfer rights of use or to allow any other use by third parties.